Recording Techniques, People Skills, Gear, Recording Spaces, Computers, and DIY

Moderators: drumsound, tomb

-

LeedyGuy

- tinnitus

- Posts: 1032

- Joined: Thu Nov 20, 2003 9:15 am

- Location: Dirty Jerzey

-

Contact:

Post

by LeedyGuy » Fri Jan 18, 2008 3:47 pm

I haven't used this a whole lot, but I got it and a coffee can full of tubes for $2 at an estate sale. It is made by Victor. I even have the repair manual for it. It needs a needle, so if anyone knows where to get one, please let me know, but I don't think it's even possible to find one at this point. Anyway, the little bitch plays a half step flat at 33 1/3 almost exactly. Any thoughts on how to fix it? I gave it a little WD40 today to loosen it up a lil bit, but still 1/2 step flat. Maybe it's a voltage thing? It is quite old, so maybe some things have changed? Maybe I need to replace the tubes to get the proper juice (not an easy task!)?

Thanks in advance for any help at all.

-Ken

-

swelle

- takin' a dinner break

- Posts: 195

- Joined: Tue Jul 27, 2004 1:46 pm

Post

by swelle » Fri Jan 18, 2008 4:49 pm

The Sound Well in Berkeley would almost definitely have a stylus.

www.thesoundwell.com

Is it belt-driven, or wheel driven? If the latter, sometimes the wheel builds up gunk and needs to be cleaned. My Garrard needs to have this done, it's a little sluggish. You might just replace the belt.

-

Nate Dort

- tinnitus

- Posts: 1039

- Joined: Mon Mar 08, 2004 6:07 pm

- Location: Detroit

-

Contact:

Post

by Nate Dort » Fri Jan 18, 2008 5:12 pm

If the belt is streched out, then that will cause it to spin slower. I replaced the belt on mine a while back, but it was still flat, so I wrapped a couple layers of electrical tape around the drive spindle to get it back up to speed.

-

RefD

- on a wing and a prayer

- Posts: 5993

- Joined: Fri Aug 27, 2004 9:10 pm

Post

by RefD » Fri Jan 18, 2008 6:28 pm

this reminds me, the right half of the pickup for the turntable in my early-60s Telefunken hifi doesn't put out any sound.

i need to more it away from the wall and troubleshoot this, but the damned thing weighs more than i do!

?What need is there to weep over parts of life? The whole of it calls for tears.? -- Seneca

-

LeedyGuy

- tinnitus

- Posts: 1032

- Joined: Thu Nov 20, 2003 9:15 am

- Location: Dirty Jerzey

-

Contact:

Post

by LeedyGuy » Fri Jan 18, 2008 10:41 pm

Thanks for the replies!

It is not belt driven. I can take a picture of the assembly that turns the platter if that would help. I doused the post that comes out of the motor and in turn spins a rubber wheel which spins the platter at the outer edge and I also doused the center post that the record goes on at the bottom because thats where it all turns. That's how I got to my current half step down state.

I will take a pic tomorrow of the assembly. I have no idea how the heck I would get under that post to clean it out though because it's pretty much attached to the motor.

-Ken

-

brianroth

- tinnitus

- Posts: 1164

- Joined: Thu Dec 09, 2004 12:32 am

- Location: Oklahoma City

Post

by brianroth » Fri Jan 18, 2008 10:57 pm

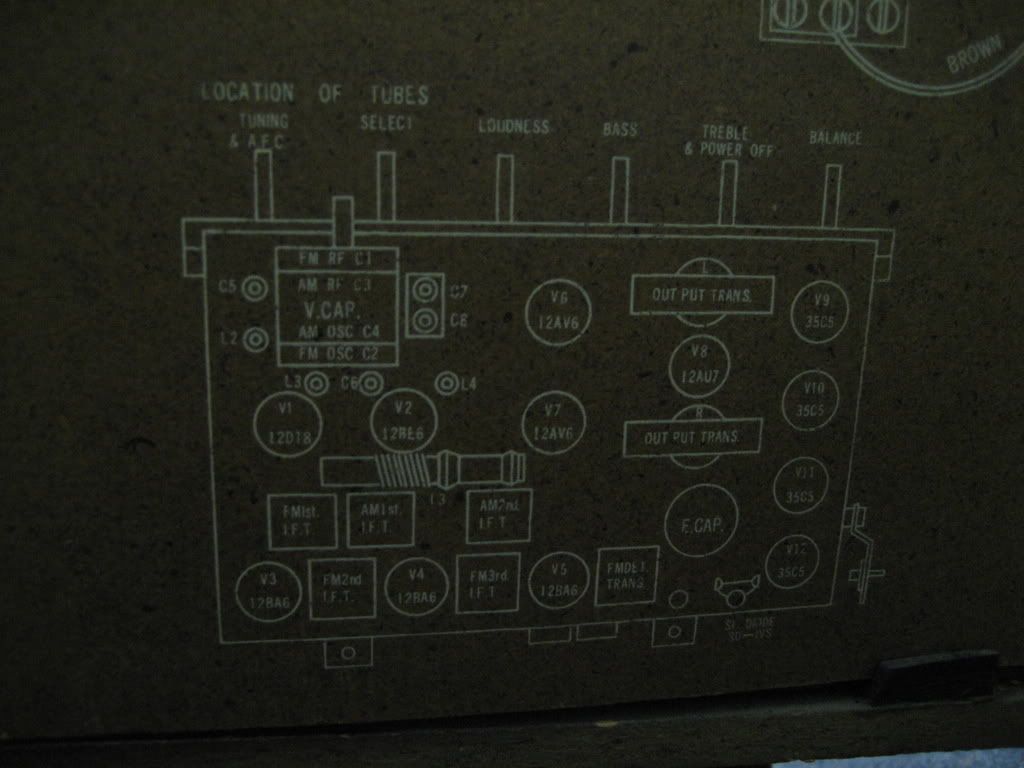

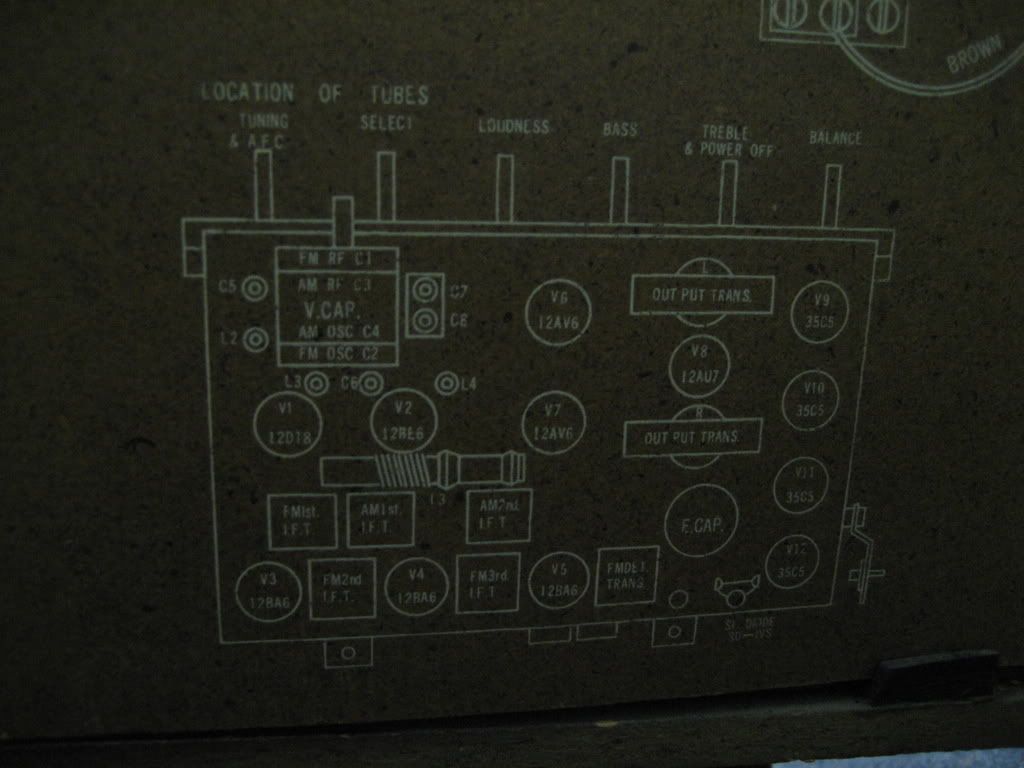

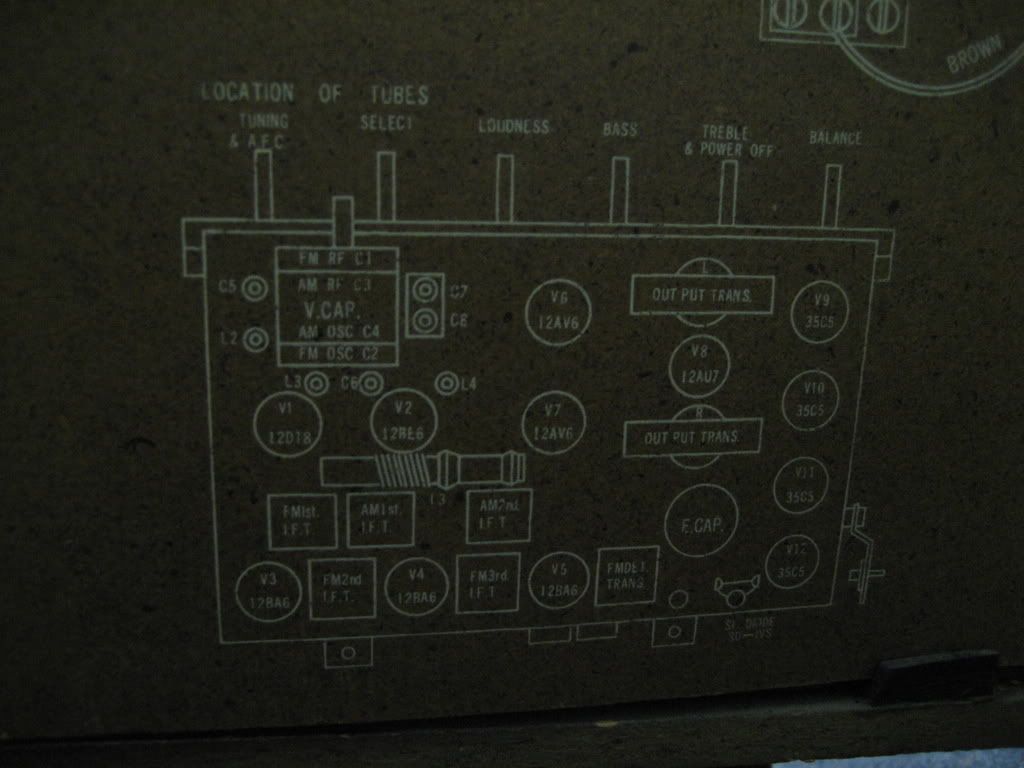

Wow...that's a cool find! One thing I noticed is the lack of a power transformer, so be aware that it will have a "hot" chassis.

Bri

-

hulahalau

- gettin' sounds

- Posts: 121

- Joined: Wed May 07, 2003 7:41 pm

Post

by hulahalau » Mon Jan 21, 2008 8:49 pm

Any turntable with a changer mechanism will be powered by a capstan wheel, not a belt. Based upon my memory rolling against the inside lip of the rim of the platter. The first thing I would do is to vacumm all dust and dirt from the mechanism. Then, dab a little solvent on the axle of the capstan wheel, pulling it away from the platter (be sure not to break the spring). Make sure no solvent gets on the rubber. Clean off the residue, and repeat. Then, lubricate with a speck of sewing machine oil - do not over-oil or it will drip and possibly get onto other parts which would not be good. I would do the same clean and relube for the axle of the platter, and see if you can also do this for the drive motor bearings. for the motor bearings, you may want to look into using a proper bearing lubricant. Whale oil is the best. but impossible to find these days.

Speed on these turntables is set by the motor-usually a synchronous motor which locks onto the 60 Hz AC. Since the power company allows this to drift slightly, you will have slight speed variations over time, but this is NOT what you appear to be experiencing.

Who is online

Users browsing this forum: No registered users and 69 guests